Products Description

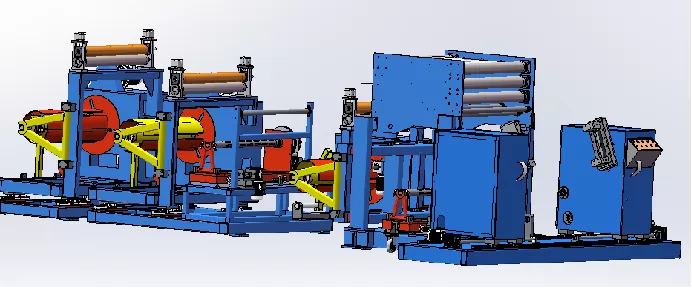

Reactor foil winding machine(Human-machine interface control, double servo clamping.)Winding) Reactor foil winding machine(Man-machine

interface control,Double servo clamp winding)

Overview: This double servo clamp core foil winding machine can directly wind the coil on the core column of the square section winding faceplate and tailstock support flower plate with the clamping arm suitable for the square core, the clamping thickness of the clamping arm can be adjusted, the adjustment mode adopts the screw rod type, the adjustment range is 0-350mm, the width of the clamping arm is 0-180mm, to adapt to the use of different specifications of cores.

Summary:This double servo core foil around the machine can coil winding directly on the square section of core column. Winding faceplate and tailstock support on the faceplate with a core clamping arm is suitable for the square,the clamping arm's clamping

thickness can be adjusted,regulating mode adopted-screwtype. Adjustment range is 0-350mm,clamping arm width O-180mm,which can adapt to different specifications of the use of iron core

Tags:

Technical parameter

Amorphous alloy special foil w

Automatic Wire Arrangement Mac

Low pressure foil winding mach

Low Pressure Foil Winding Mach

Main technical parameters:

Main technical parameters

Parameter model | BRJ-400-2 | BRJ-600-2 | BRJ-800-2 |

Coil processing rangeRange ofcoil processing | |||

Axial lengthAxial length | 400mm | 600mm | 800mm |

Axial length (including leads) Axia length(including led wire) | 450mm | 650mm | 850mm |

Outside diameterMAX FROM(Max) | 800mm | 800mm | 800mm |

Inner diameterMIN(Min) | 10mm | 10mm | 10mm |

Coil formCoin shape | rotundity/rectangleRound/Rectangular | ||

Coil materialCoil materia | |||

MaterialMateria | Copper foil/aluminum foilCopper foil/Aluminum was | ||

WidthWidth | 400mm | 600mm | 800mm |

thicknessThickness | Copper foilCopper foil:0.2-2mmAluminum foil:0.2-3.0mm | ||

UncoilerUncoiler | |||

Effective length of the barrel Rackshelf usefullength | 450mm | 650mm | 850mm |

Material-bearingThe size of the expansion and contraction of the cylinderRack shelf swell-shrink size | 0420-0540 | 0420-0540 | 0420-0540 |

Bearing barrel bearingRack shelf load bearing | 1000kg | 1500kg | 2000kg |

Tension forceSwelling force | 0-6000N. M | 0-8000N. M | 0-10000N. M |

Tension working pressure Swelling working force | 0-0.6MP | 0-0.6MP | 0-0.6MP |

Winding machineWinding machine | |||

Winding power(Dual servo motors) Winding power | 4.3+4.3KW | 5.5+5.5KW | 7.5+7.5KW |

Winding speedWinding speed | 0-40r/min | 0-40r/min | 0-35r/min |

Layer insulated uncoiling deviceLayer insulation uncoiling device | |||

Number of layer insulationsLayer insulation officialtita | 1 | 1 | 1 |

Outer diameter of layer insulationLayer insulation roll FROM | ≤400mm | ≤400mm | ≤400mm |

Layer insulation inner diameterLayer insulation roll ID | 76mm | 76mm | 76mm |

layer insulationwidthLayer insulation roll wiGermanh | ≤450 | ≤650 | ≤850 |

Guiding deviceRectifying deviation device | |||

Deviation correction methodRectifying deviation mode | lightElectrically inductive automatic deviation correctionPhotoelectricsensing automatic rectify deviation | ||

Guiding accuracyRectifying deviation precision | ±0.4mm | ±0.4mm | ±0.4mm |

Electronic control systemElectric system | |||

Control modeControl mode | PLC automatic control mode: PLC automatic contro | ||

Count digitsCounting digit | 0-9999.9 | ||

Counting accuracyCounting precision | 0.1 turns and 0.1 Trimmed | ||