Products Description

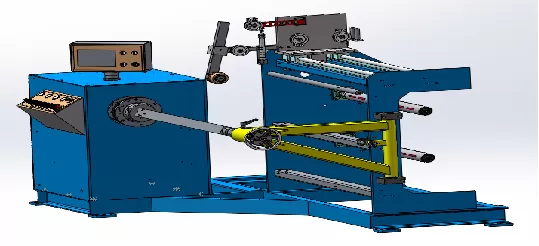

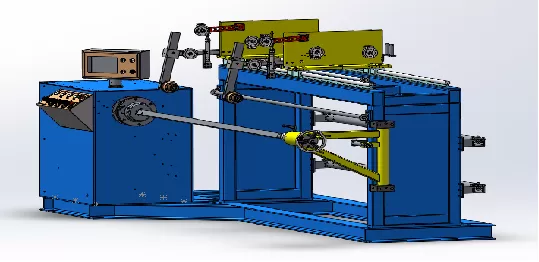

Automatic winding machine

automatic winding machine

Overview: The automatic winding machine is suitable for all kinds of small and medium-sized distribution transformers, transformers, reactor coils and similar processes coil winding.

Summary: type automatic winding machine is suitable for all kinds of smal and medium-sized distribution transformer、mutual inductor、reactor coil and similarly coil winding process

Wound by the host By the winding host

Automatic cable arrangement Automatic wiring devices

layer insulated supply device Layer insulation supply device Round wire, flat wire tension adjustable pay-off frame

Adjustable motorized round wire and lat wire tension Air-operated system

PLC control and servo motor system

PLC control and servo motor system touch screen human-machine interface

Touch screen and man-machine interface

Tags:

Technical parameter

Amorphous alloy special foil w

Automatic Wire Arrangement Mac

Low pressure foil winding mach

Low Pressure Foil Winding Mach

Main technical parameters:

Main technical parameters

1 | Center highCentre height | 850 mm | 900 mm |

2 | Spool center distanceCenter distance around the axis | 0-800mm | 1000mm (cable range) |

3 | Working force distanceWork torque | max 1000 NM | max 1000 N/M |

4 | Spool sizeAround the spool size | 50×90 | 40×40×1200 |

5 | Working speedWork speed | 0—200 r/min | 0—240r/min |

6 | Speed regulation modeSpeed method | Stepless frequency conversion speed regulationStepless frequency control of motor speed | Stepless frequency conversion speed regulation |

7 |

Applicable workpiece range Applicable scope of artifacts | Outside diameter(o.d.)≤600mm Outer diameter(o.d.) ≤600mm | Outside diameter(o.d.) ≤750mm |

Inner diameter(i.d.)=80mm Inner diameter(i.d.)≥80mm | Inner diameter (i.d.) ≥80mm | ||

Axial height:H ≤750mm Axial height:H ≤750mm | Axial height: H ≤1000mm | ||

8 | Rectangular coil diagonal length:Rectangular coil diagonal length | Max: 800 mm | Max: 1000 mm |

9 | Workpiece weight:Workpiece weight | Max:500kg | Max:650kg |

10 | Number of layer insulationsLayer insulation quantity | 2 twos | 2piece |

11 | The power of the whole machineMachine power | about5 kw About 5 kw | about7kw About 7 kw |

12 | The maximum number of laps set by the counterMaximum set number of counter turns | 9999.9 | 9999.9 |

13 |

Wire specificationsWire specification | Flat wire: Max 3×12mm Flatwire: Max 3×12mm | Flat wire: Max 3×15mm Flatwire: Max 3×15mm |

Enameled wire:φ0.8mm—φ3mm Enameledwire:φ0.8mm—φ3mm | Enameled wire:φ0.8mm—φ5mm Enameledwire:φ0.8mm—φ5mm | ||

14 | Automatic cable arrangement Automatic line function | Adjust the minimum spacing of the wire diameter0.01mm Adjust the wire diameter minimum spacing of 0.01 mm | Adjust the minimum spacing of the wire diameter0.01mm Adjust the wire diameter minimum spacing of 0.01 mm |

15 | power supplyPowersource | 380v50HZ | 380v50HZ |